By Product Category

Order-made Parts

WEDGE WIRE SCREEN

WHAT IS WEDGE WIRE SCREEN?

The wedge wire screen has slits which are formed to fit each use by arranging wedge-shaped profile wires in parallel at equal intervals. It is a multi-purpose screen with the features of reduced possibility of clogging and sturdy and precision-made construction.

FEATURES OF THE WEDGE WIRE SCREEN

1.LESS BLINDING AND HIGH DEWATERING EFFICIENCY

The screen's blinding or clogging is reduced and therefore its dewatering efficiency becomes high, since its contact area with solids passing through is small because of the wedge-shaped profile of wires. Furthermore, the screen's backwashing efficiency is high with the result that its maintenance is easy.

2.HIGH-PRECISION AND STURDY CONSTRUCTION

As compared with conventional woven wire cloths, this screen can form finer slits with thicker wires.

3.BROAD FLEXIBILITY IN DESIGN

The screen is so flexible in workability that it can be formed into various shapes such as flat panels, cylinders, cones, etc.

4.FLAT SURFACE

The screen's flat surface insures the smooth flow of processing materials, catalysts, etc.

MATERIAL OF THE WEDGE WIRE SCREEN

STANDARD MATERIAL : SUS304

Other materials like SUS316L, titanium, nickel alloy, etc. will be available depending on the screen's uses

CLASSIFICATION OF THE WEDGE WIRE SCREEN

WELDED TYPE

WEDGE WIRE SCREEN

This is a screen with slits which are formed by pressure-welding cold-formed wires to support rods

LOOPED TYPE

WEDGE WIRE SCREEN

This is a screen with slits which are secured by threading the loops cold-formed by a press out of raw circular wires with rods.

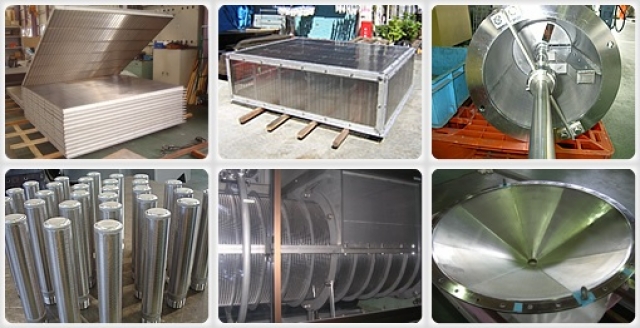

EXAMPLES OF SHAPES MADE OUT OF THE WEDGE WIRE SCREEN

We prepare a wide variety of original parts to meet our customers' detailed needs. We make it a practice to manufacture a broad variety of products in a small lot for each.

APPLICATIONS OF THE WEDGE WIRE SCREEN

・Parts for machinery such as strainers, centrifugal separators, dewaterers and vibrating screens.

・Intake of river water and sea water.

・Supporting of activated charcoal, ion exchange resin, catalysts, filtering media and so forth.

・Prevention of carriers from flowing out.

・Strainers' elements.

We receive inquiries from customers on their uses, requested shapes and others by telephone, facsimile or e-mail.

Contact

Please wait while the form appears.

If the form doesn't appear even after waiting for a while, please contact here.